Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

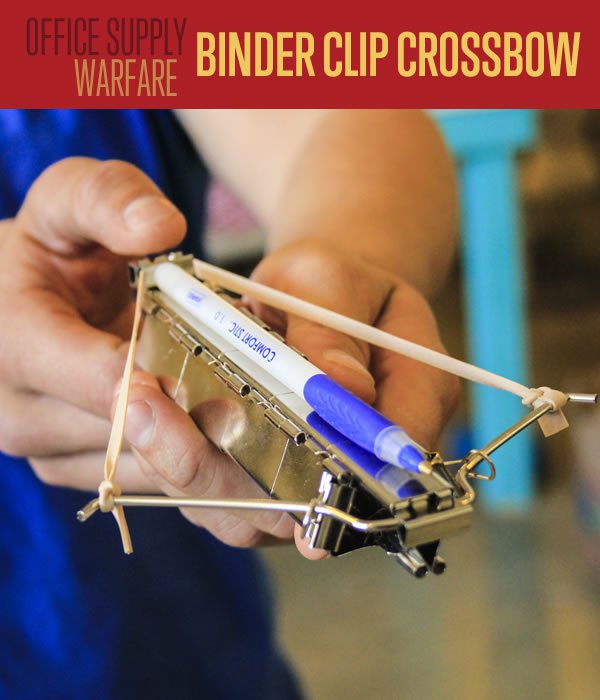

Great easy lightweight bow thank you for sharing it.

ummmm. honestly, I prefer PINK bows. k bye

besties,

kikko

Cool post. I would love to try and make this! Thanks for sharing!

-Sara

Do you know what the draw weight in this is?

Hi Jess!

We did do a test of the draw weight, after we finished posting the tutorial, it came out to around 60LB draw. We found also that by shortening the bow string by 5 more inches, helped make the draw bump up closer to 65 pounds.

-Sean

-Sean

Thanks Sean! That’s perfect!

Draw length?

Hey Carlos,

My draw length, when measuring the draw weight, was 27inch.

Very nice twist on the simple “fiberglass fortified” PVC longbow!

Your insert idea for keeping the rods in place is perfect.

Now, for those who don’t know about bow strings I offer these videos:

The most simple “real” string you can make (one loop):

https://www.youtube.com/watch?v=RzZCfoopOKk

Beyond that you would need a string board to make an actual 2 loop Flemish string:

https://www.youtube.com/watch?v=C07evRZT_PQ

I use 550 paracord strings too, but real strings will get your arrow speed up significantly. Buy a roll of B-50 Dacron bow string material and some string wax/beeswax off Amazon (cheap) to make the simple one loop string shown in the first video. One roll will make *many* strings.

Also, for beginners, get some full length aluminium Easton XX75 Genesis NASP arrows. Sold on Amazon or Lancaster Archery. The shaft size/diameter is 1820, perfect for these PVC bows. Thin yet durable. Lancaster Archery and 3 Rivers Archery sell the 1820 threaded front inserts to turn those target arrows into hunting arrows.

Have you considered making arrows from some of the same fiberglass rods as used in the bow?

Split a chicken, crow, Sea Gull, whatever wing feather and bind short (2″) lengths to the nock end sealing the binding with 5 minute epoxy. I’ve used flattened steel pop or beer bottle caps to make arrow heads. Flatten ’em out bend ’em over a drill bit shank or piece of round stock the size of the arrow and glue ’em on with good ol’ 5 minute epoxy, AKA 2 part pine pitch. Bottle cap arrowheads make a very nasty wound, so be careful, a decent hunting head can be made from a small bit of steel from a 55 gal drum or defunct car fender or anything similar. Or just sharpen the point of the shaft with sandpaper or a file.

i’m guessing you have no real experience with a bow at all. judging from the picture of you drawing the bow, it seems that you don’t have very much archery knowledge. also, using round pipe is actually a very ineffecient way to use pvc as a bow. if you would like to see what can be done with this material, https://plus.google.com/?gpsrc=gplp0#communities/115443350092709812365 this is agreat place to start. hope this helps.

Have you ever considered using a heat gun and a 2×4 to flatten the limbs? I imagine that it would be a bit less costly seeing as how you would only be using one piece of pipe, and flattening it would evenly distribute the tension/compressive forces than just a round pipe.

I also that it would perform a little better since the tips of the resultant bow would be considerably lighter

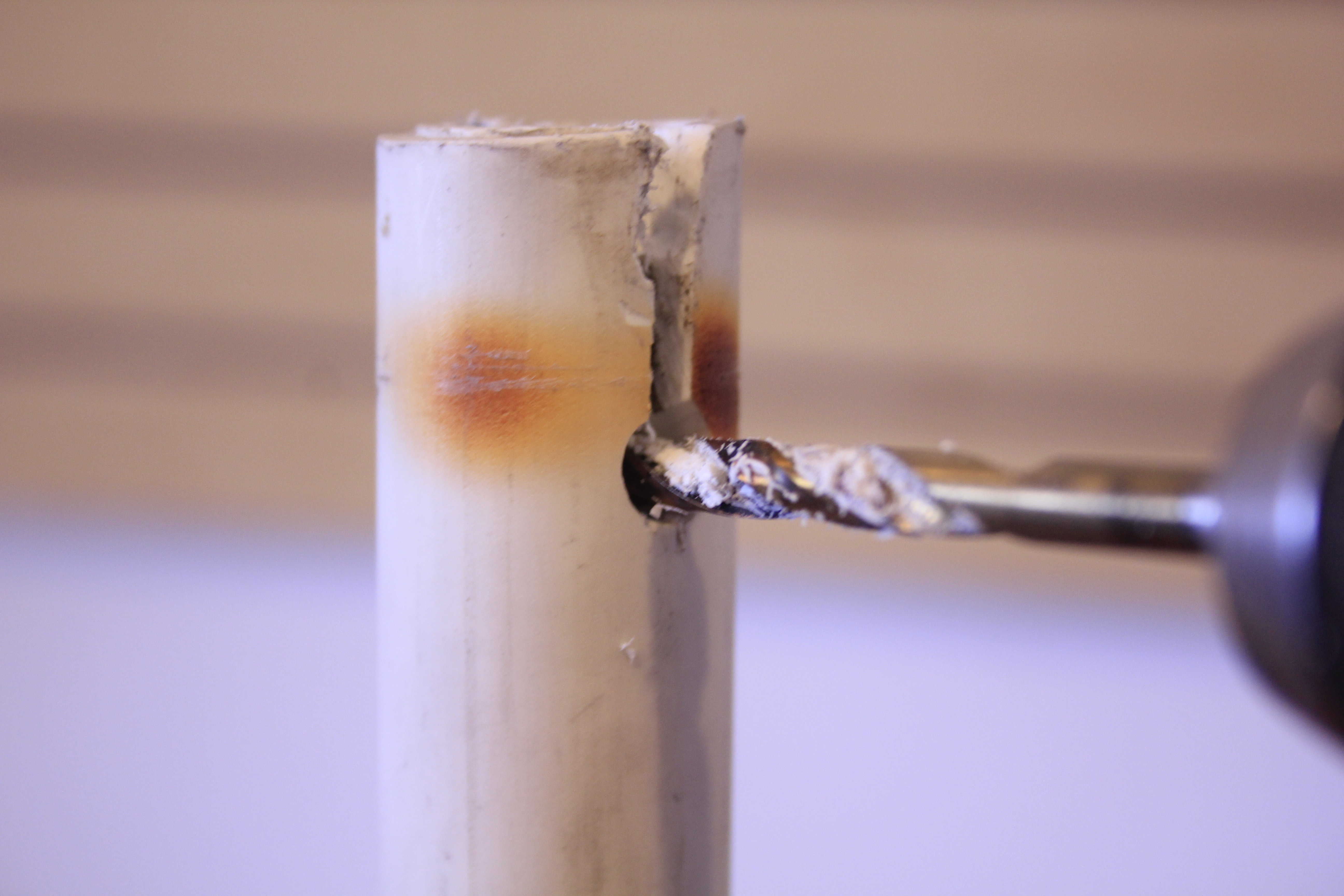

Really neat project. Question about step no. 7, the pvc pipe shows heat marks, did I miss something in the instructions or was this just left over from another project?

Also I know from my bows that I have to keep the string waxed or the strands get frayed and break prematurely. Have you had any trouble with the paracord string, and how long does the string last?

Thanks, great work!

Would you shorten the length of the bow for younger kids? My son is 10 and I don’t want it to be to long for him.

Hey Heather,

Yes, I would cut the length down. You can look up bow dimensions at online stores, look for youth bows sold in stores, and make your son’s an equal length to one sold in store for his age/height. Follow the same instruction for stringing it, make it shorter then the bow length.

Also, don’t use the fiberglass rods for pre-teen youth, only use those for adult archery or if using the bow for a make shift survival hunting bow. You don’t want an adult bow with lots of draw weight for him to start out on.

We have more bow making courses coming soon, including traditional wooden bows, and sling shot bow out of pvc, perfect for kids shooting at targets in back yard under adult supervision.

I really liked your bow tutorial. I’m into making bows and arrows with my kids and my little sister. I tried looking in your site for an arrow tutorial but had no luck. Can you please send me the link. I appriciate it a lot. Thank you and keep up the good work. 🙂

Hi Sean it all looks good and simple; however, I have one big problem, that is sourcing the fiberglass rod reflective road markers. These are not items I can pick up in Guyana. So where can I get them to buy?

I can’t find the fiberglass reflective rod where i am. What can i use as alternative?