Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

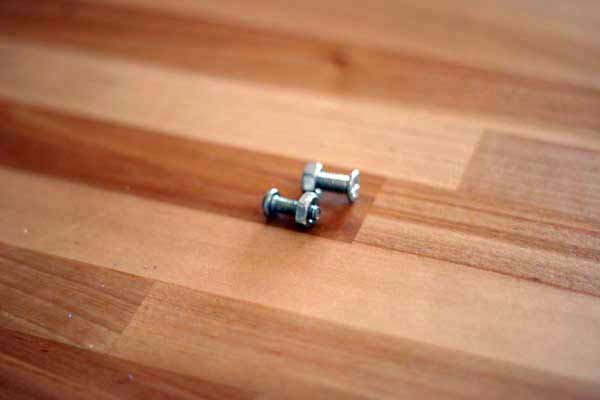

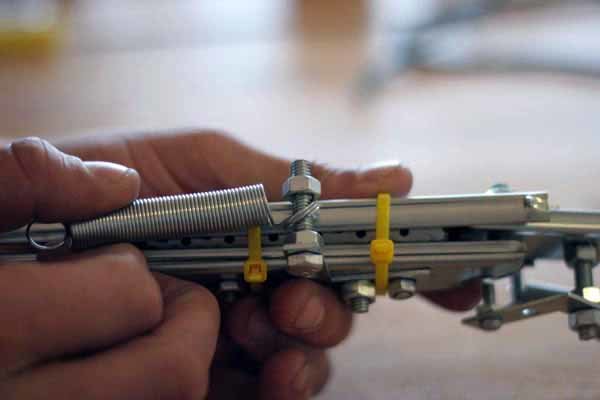

Please use correct nomenclature regarding bolts. Your main bolts look like 1/4-20 x 2″, etc. Also in the workup you say compression rather than tension springs.

Choppy Bangs: it is also a modified variation of blunt haircut.

The hair is cut such a way that the top of the hair appears like a flat surface.

Not all hairstyle will have the same impact on your face except for the few.