Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

Source for this related gaming news is as simple as you click This website and read another one!

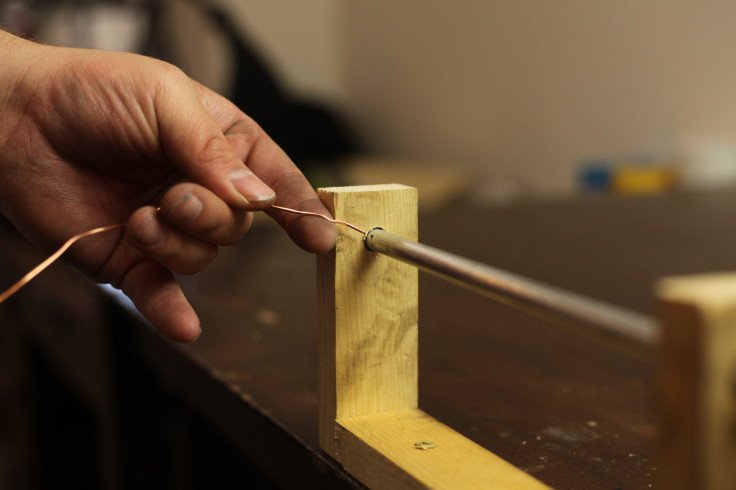

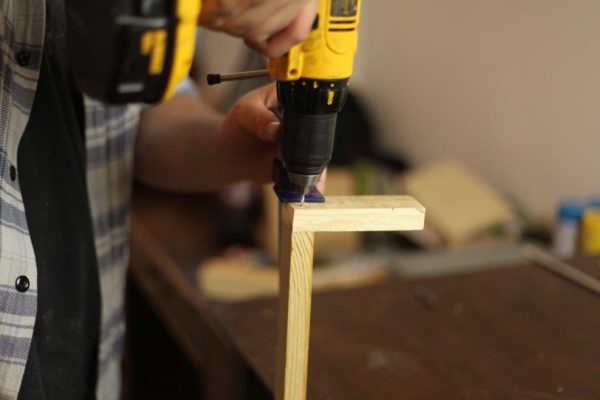

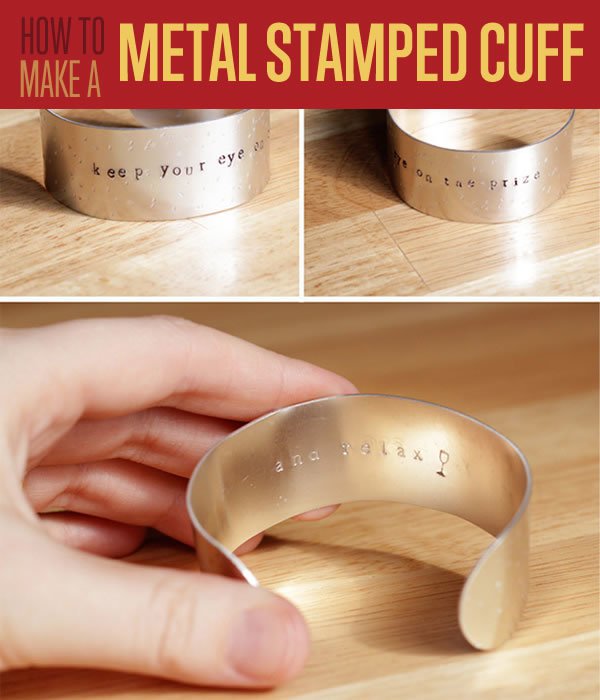

seriously, after all that work to created your own mandrel and rings you might want to saw your links and make them nice instead of using wire cutters